Strasbourg, December 20th, 2022 – Autonomous factory powered by AI and flow chemistry.

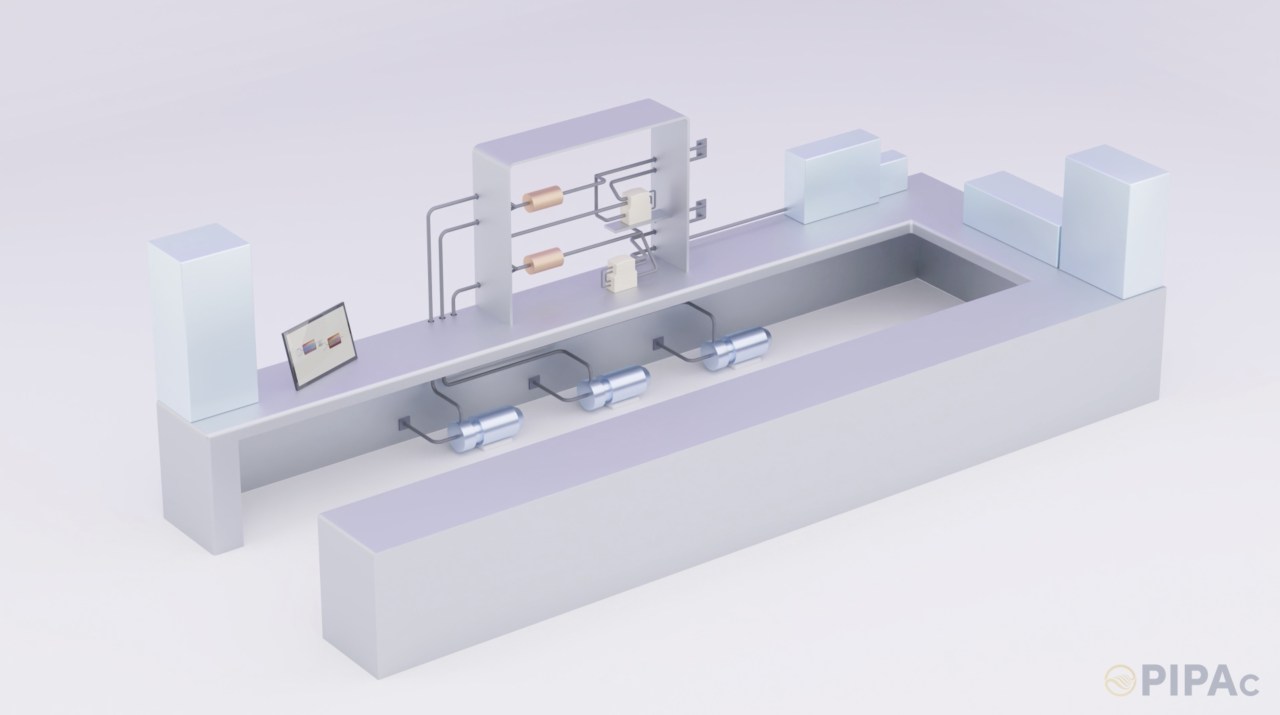

PIPAc (Production Intelligente de Principes Actifs) will bring the first AI-powered autonomous industrial demonstrator for active pharmaceutical ingredients (APIs) manufacturing. The outcome is high-quality API production, safer by design. The innovation relies on several key ingredients: continuous flow chemistry, artificial intelligence, and additive manufacturing. In flow chemistry, chemical reactions are performed in a continuous flow, rather than in batch mode. This allows for better control and optimization of the reaction conditions, leading to higher yields and better product purity. Continuous flow chemistry approach can also reduce the amount of produced waste and reduce energy use. A small amount of any intermediate reaction products guarantees a safer process at all times. Additionally, this approach is easier and faster to scale-up, reducing time to market, and is compact.

Therefore, it allows for mobile production on-demand, which is highly relevant for this application. Artificial intelligence (AI) takesthe advantages of flow chemistry one step further by adapting synthesis parameters in real-time to an ever-changing environment. For example, the flow rate is adapted to any fluctuations of the reactor temperature to guarantee the best yield. Available 24/7, AI will reduce operator’s stress and thus reduce the risk of making a mistake. Another feature enabled by AI will be predictive maintenance of the installation.

Finally, additive manufacturing (3D printing) is changing the way we design the process. We manufacture chemical reactors tailored specifically to the reaction.

By using customized design and materials, we improve mixing properties, heat transfer, chemical resistance, and other characteristics. This enhances reaction

performance, while further reducing energy consumption.

Access the full press release